2025/09/28

2025/09/28

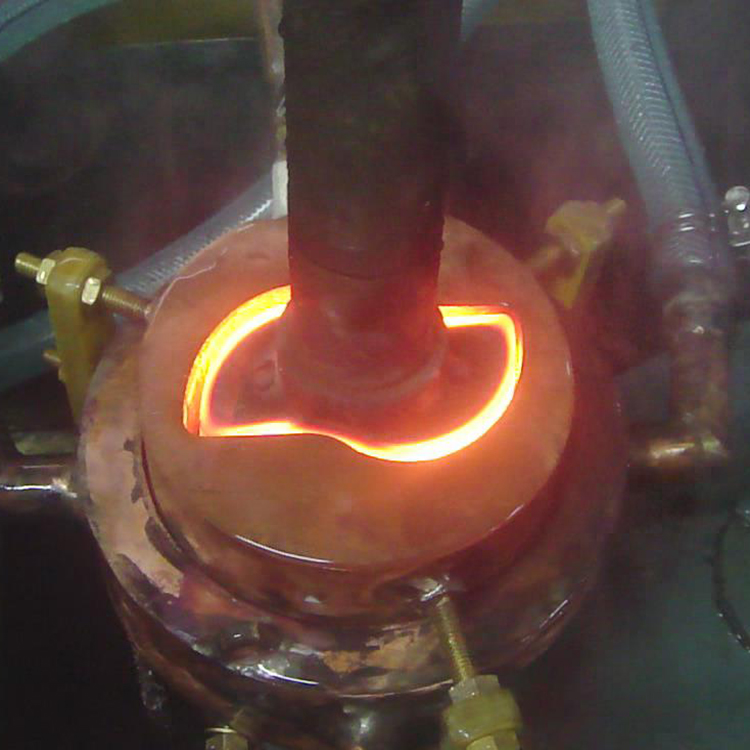

Overview of Brake Shaft Quenching Equipment

The brake shaft quenching equipment is mainly used for the heat treatment process of brake shafts in automotive brake systems, with the aim of improving the performance of brake shafts and extending their service life. As a key component in the automotive braking system, the brake shaft bears enormous friction and pressure during operation, thus requiring high strength and wear resistance. By quenching treatment, the surface hardness, strength, and wear resistance of the brake shaft can be significantly improved. one

The function of quenching equipment

Quenching equipment mainly includes induction heat treatment equipment and CNC quenching machines, which achieve quenching treatment of brake shafts through different heating and cooling methods. Induction heat treatment equipment uses the principle of electromagnetic induction to heat the workpiece and rapidly cool it through a cooling medium to improve hardness and wear resistance. Numerical control quenching machine tools can control the quenching process through programming, achieve automated production, and improve production efficiency and product quality. twenty-eight

Quenching process flow

The process flow of brake shaft quenching includes temperature control and preheating treatment, quenching process and process parameter selection, cooling method, and subsequent heat treatment process. During the entire process, it is necessary to test and analyze the surface hardness, and conduct metallographic analysis on the structural changes to evaluate the quenching effect. one

Instructions for using quenching equipment

The use of quenching equipment involves multiple steps, including setting process parameters, clamping workpieces, starting equipment, etc. During use, operators need to choose the appropriate quenching process and parameters based on the material and quenching requirements of the workpiece, and conduct strict quality control to ensure the quenching effect is achieved. fourteen

Key points of equipment maintenance

The maintenance of quenching equipment is key to ensuring long-term stable operation, including regular inspection of induction coils, cleaning of cooling systems, and inspection of electrical systems. Proper maintenance can improve the service life and effectiveness of equipment, and reduce the failure rate. fifteen

conclusion

In summary, the brake shaft quenching equipment plays a crucial role in the automotive braking system, as it not only improves the performance of the brake shaft but also ensures the safety of driving. With the continuous advancement of technology, the types and techniques of quenching equipment are also constantly developing and improving, providing strong support for the automotive manufacturing industry. When using and maintaining quenching equipment, it is necessary to strictly follow the operating procedures to ensure the normal operation and service life of the equipment.